Thermo Mechanically Treated (TMT) bars stand as a cornerstone in the construction industry, offering superior strength, ductility, and resistance to seismic forces. In this comprehensive blog, we'll embark on a journey to unravel the intricacies of TMT bar Production Cost of Thermo Mechanically Treated (TMT) Bars, exploring the factors shaping pricing dynamics, dissecting production processes, and gaining insights into the industry landscape.

Understanding TMT Bar Production

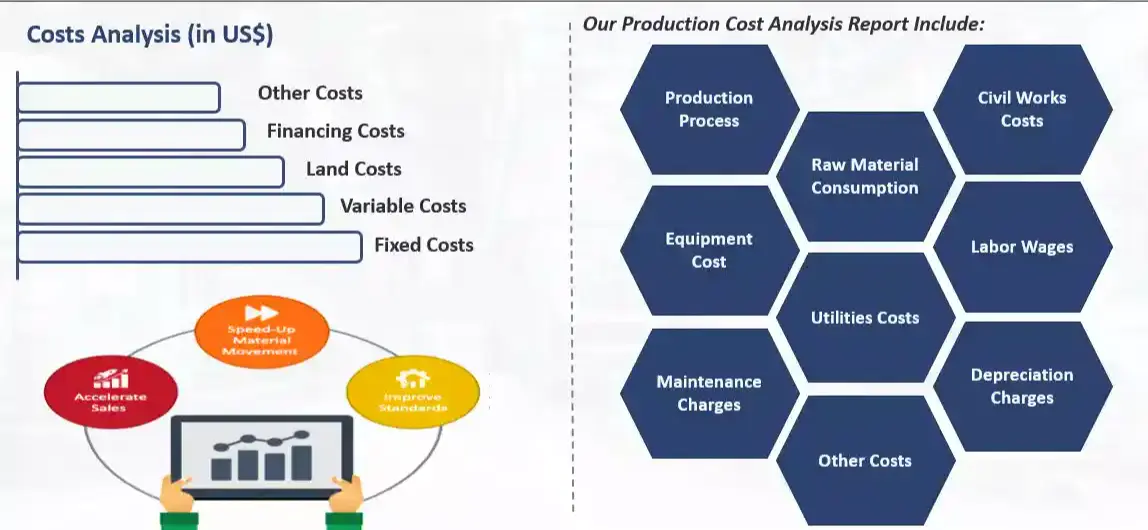

Thermo Mechanically Treated (TMT) bars are produced through a series of sophisticated manufacturing processes, aimed at enhancing the mechanical properties of conventional steel bars. The production cost of TMT bars is influenced by various factors, including raw material prices, energy expenses, technological investments, and quality control measures.

Request Free Sample: https://www.procurementresource.com/production-cost-report-store/thermo-mechanically-treated-bar/request-sample

Factors Influencing TMT Bar Production Cost

-

Raw Material Prices: The cost of raw materials, predominantly steel billets, significantly impacts the production cost of TMT bars. Fluctuations in steel prices, influenced by global demand, supply dynamics, trade policies, and raw material costs (such as iron ore and coal), directly affect the overall production cost.

-

Energy Expenses: TMT bar production involves energy-intensive processes, including melting, rolling, and quenching operations. Energy costs, encompassing electricity, natural gas, and fuel, constitute a substantial portion of the production expenses. Efficiency improvements, technology upgrades, and energy conservation measures contribute to optimizing energy consumption and reducing production costs.

-

Technological Investments: TMT bar manufacturing requires significant capital investment in production facilities, machinery, and equipment. Technological advancements, such as automated rolling mills, computerized process control systems, and advanced heat treatment furnaces, enhance production efficiency, quality control, and output consistency, albeit at higher initial costs.

-

Quality Control Measures: Ensuring product quality and compliance with industry standards necessitates investments in quality control measures, including material testing, process monitoring, and product certification. Stringent quality assurance protocols, laboratory testing facilities, and adherence to regulatory requirements add to the production cost but are essential for maintaining product integrity and customer satisfaction.

Analyzing TMT Bar Production Processes

TMT bars undergo a series of sequential processes to impart desired mechanical properties, including strength, ductility, and corrosion resistance. The production process typically involves:

-

Melting: Steel scrap or iron ore is melted in electric arc furnaces or induction furnaces to form molten metal.

-

Casting: The molten metal is cast into billets or blooms, which serve as the primary raw material for TMT bar production.

-

Rolling: The billets are heated and passed through rolling mills to achieve the desired shape, size, and mechanical properties.

-

Quenching: The hot rolled bars are subjected to rapid quenching in water or polymer solutions to induce controlled cooling and structural transformation, imparting strength and toughness to the bars.

-

Tempering: The quenched bars are reheated and tempered to relieve internal stresses and improve ductility and weldability.

Industry Insights and Market Dynamics

The TMT bar industry is shaped by various market dynamics, including construction activity, infrastructure development, real estate trends, regulatory policies, and technological advancements. As a critical construction material, TMT bars are integral to infrastructure projects, commercial buildings, residential complexes, and industrial facilities, driving demand from the construction sector. Moreover, factors such as urbanization, population growth, government initiatives, and environmental regulations influence market dynamics, pricing trends, and competitive landscape in the TMT bar industry.

Conclusion

In conclusion, the production cost of Thermo Mechanically Treated (TMT) bars is influenced by a myriad of factors, including raw material prices, energy expenses, technological investments, and quality control measures. Understanding these factors is crucial for TMT bar manufacturers, policymakers, and stakeholders to navigate the complexities of the industry effectively. By optimizing production processes, leveraging technological innovations, and implementing quality assurance practices, companies can enhance competitiveness, mitigate production costs, and meet the evolving demands of the construction industry. As a fundamental component in building infrastructure and driving economic growth, TMT bars continue to play a pivotal role in shaping the future of construction and development worldwide.